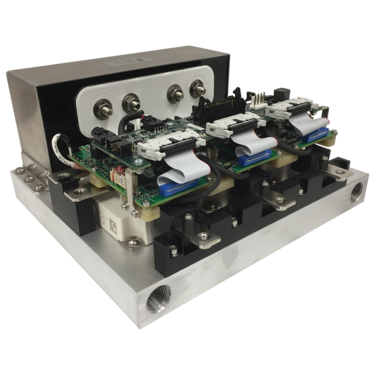

Power Stack Design, Manufacturing & Testing

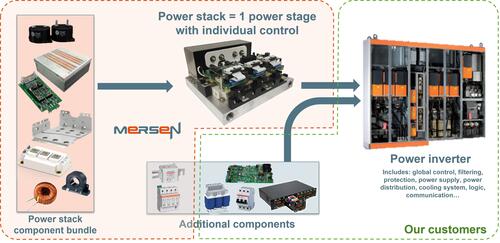

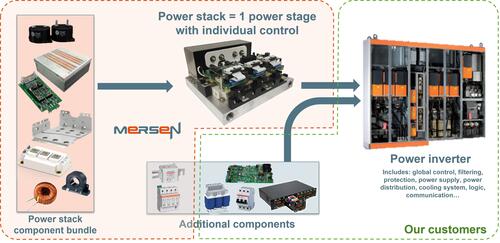

When it comes to designing power inverters and converters, our customers require power stages or power stacks with enhanced power density (kW/liter) while minimizing conversion losses (Efficiency %), reducing cost ($/kW) and reducing size and weight of the overall system. Thanks to its undisputed reputation in bus bar, cooling, fusing, capacitor design, and manufacturing, Mersen is your preferred partner to assist you during the development phase of your Silicon (Si), Silicon Carbide (SiC) or Gallium Nitride (GaN)-based power stack, bringing a technical cross-expertise on these 4 key products to push the optimization to the limit.

From prototypes to volume manufacturing

From a few prototypes to volume manufacturing, Mersen is your preferred partner to assist you during the development phase, the testing, the qualification followed by the sampling, the volume ramp-up and finally the industrialization of your Silicon (Si), Silicon Carbide (SiC) or Gallium Nitride (GaN)-based power stack.

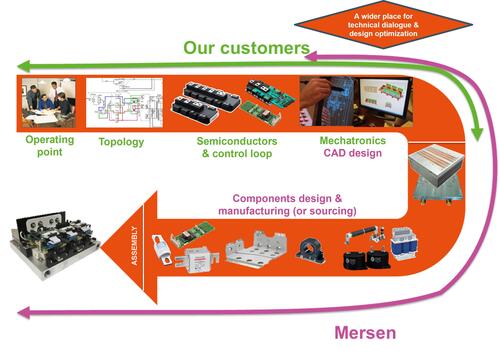

Co-development and design optimization

Whereas the final application ultimately drives the inverter operating point seting, our customers are designing the most appropriate topology and control to power this application. From this topology, Mersen is capable of turning a virtual CAD design into a real piece of technology thanks a tight co-development work.

Using multipple design optmization iterations, Mersen is helping their customers achieving the best possible design, taking into account both, mechatronics and electronics constraints and challenges.

Mersen is using complete tool-set of simulation software in order to compute any designs in all physical dimensions: Mechanical, Thermal, Electrical, Electromagnetics. These tools allow us to anticipate the multi-physics interactions between all the components and thus, to select these components in an optimal mix.

Value proposition

• Conception optimization and design cycle-time reduction, with testing and design validation in our labs

• Single-face project management. No need to manage multiple suppliers in sync.

• Preferential access to main components

o Mersen-made cooling device, bus bar, capacitors and fuses

o Preferred suppliers for power modules, gate driver, current sensors, and others

• Overall price optimization / scale effect.

• A total customization approach: no pre-defined technical bricks.

o Dimensions, footprint, geometry

o Circuit topology: 3-level, NPC, ANPC, bi-directional, DC-DC, back-to-back…

o Gate driver: hard switching, soft switching, zero-voltage switching (ZVS)

o Cooling type: Air, liquid, heat-pipe…

o Power range, current rating

o Switching Frequency Fsw

o Voltage: 650V, 1.2 kV, 1.7 kV, 3.3 kV modules or more

o Semiconductor technology: SiC MOSFET, Si IGBT, GaN HEMT…

o AC-filtering

o Many more on demand…

Targeted customers

• Inverter / Stack design-house with limited or no production capability.

• OEM / stack and inverter manufacturers: specialists and generalists.

• System Integrators: When defining converter is not core business.

A global footprint

Our center of excellence for design, including assembly / test services for low and medium volumes is located in the United States. The vast majority of the constituent parts used for stack assembly are designed and manufactured in Mersen facilities all over the globe with dual or triple sourcing capability. Our partners and tier-one suppliers also offer dual sourcing strategy.

Our power stack manufacturing footprint includes:

• “Stack Lab”: Prototyping and small series

o Now operating in Rochester, NY – USA

• Pilot Line: Volume ramp-up and mid-size series

o Located in Rochester, NY – USA

o Equipped with an automatic test bench and customer specific power loads.

o Will be operational starting from H2 2024

• Series Line(s): Volume manufacturing

o Customer specific

o Local-to-local approach: Will be operating in North or South America, Europe, or India according to final customer supply-chain strategy.

Power Stack Evaluation Kits

Mersen SiC Power Stack Evaluation Kits help inverter designers save time and confusion in selecting individual components and can greatly benefit from a solution that is optimally pre-designed for their specific application.